Press shop

The task of our press shop is to produce, in the best possible quality, from metal sheets and coils the frame parts that will be forwarded to the body shop.

The task of our press shop is to produce, in the best possible quality, from metal sheets and coils the frame parts that will be forwarded to the body shop.

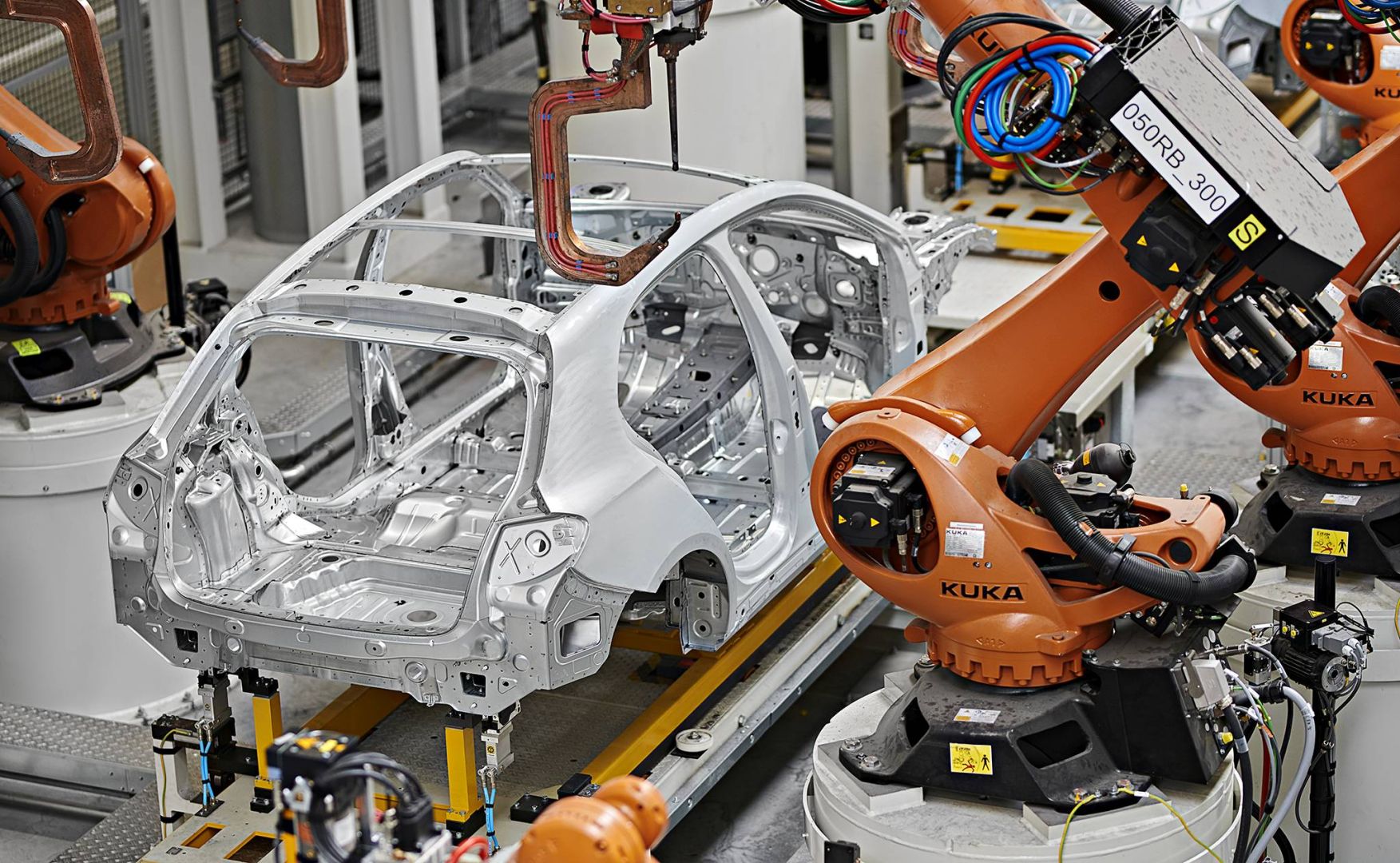

In our body shop we join the parts to build the body shell, which, after being dried, will get into the body sorter. This is the shop where cars obtain their outer shape and form.

In our paint shop, after a process called pretreatment, bodies receive protection against corrosion and then they are painted in the color the customer ordered.

In our assembly shop the internal parts are built in the car in accordance with the unique customization by the client's order.

Our well-organized, just-in-time logistics background ensures that all the components and materials are provided and available for the production of cars by the right time and place and in appropriate quantities.

Quality control ensures that every Mercedes-Benz car leaves our plant in Kecskemét in premium quality. Thanks to our motivated and highly qualified team we always comply with our customers' wishes and the highest of standards.

The task of finance and controlling is to provide the appropriate finance planning for the strategic goals and organization of our plant.

The acquisition team in Kecskemét carries out the purchase of so-called non-productive materials and services, which are materials, assets and services that are not actually built in the cars.

Our HR department is responsible for the comprehensive personnel planning and development at our plant, including the recruiting and fitting-in of new employees, organizing and realizing training courses and vocational education.

The informational technology team of our plant is in charge for controlling and checking automated data processing, operating production control and controlling systems, for IT security and operating telecommunication systems.

Factory planning is responsible for the planning, coordinating and realization of new investments, working together with the authorities.

At our plant the safety of individuals and machines is an issue of the same importance as the quality of work. Our production technology department is responsible for the constant operation of the establishment, for maintenance, fire protection matters as well as for the vehicle fleet and plant safety.

The goal of production and logistics planning at our plant is to enable us to carry out our tasks in the most effective manner. With the assets and means available to us we are able to manufacture the best cars of the world in the fastest possible way. We know exactly how much time it takes to build a car. We know how many of our employees need to work, what tools and equipment we need to manufacture a Mercedes car. One thing is for sure: no component will ever arrive too late or get to the wrong side of the assembly line.

Areas related to plant management include legal and compliance issues, work and environmental protection, Mercedes-Benz Production System (MPS), productivity development and corporate communication.